This month we delivered our new equipment data service (EDS) capability to more than 150 customer organizations globally. Leading customers adopted the system shortly after release of Scale-up Suite 2 in July 2021; now we are formally going live for everyone.

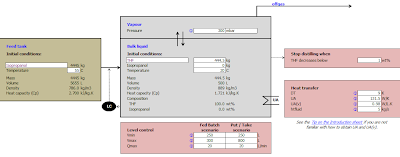

This SQL database backed approach to managing your equipment data has many advantages compared to the old system of requiring users to find and import our industry-standard Excel-based template, in use since 2011. It is also the only supported way to retrieve your equipment data into the latest version of our mixing and heat transfer toolbox after 30 June 2022.

Features include secure user account based access control, easy access from any device and a change log for traceability.

We have made the administrators of your EDS the same people who are administrators of your Dynochem license. We have sent your admins (custodians of your database) simple instructions to populate the service with your equipment information and make it available to you. For users, as this capability is rolled out, you will start to see the Vessel Update button becoming active in your Dynochem 6 ribbon. Other benefits of adoption include:

- Your continued ability to use the latest version of the mixing toolbox with your equipment data after 30 June. The toolbox will no longer have an Excel file Import button, so the only way to include your organization's equipment in the toolbox will be using the EDS (Vessel Update button in the ribbon)

- The latest version of the toolbox (30 June) will include a fuller range of Mettler Toledo lab vessels you can easily choose, apply or edit for your applications

- Users no longer need to know ‘where the vessel database file is’, to copy and paste it's web address or to browse to locate it on the network

- Users can access equipment information in any Excel workbook, using the Catalist and Properties buttons on the DC Excel ribbon

- Users on any device can access and view your equipment through a simple web browser interface; they do not need Scale-up Suite installed to do this; they need only to have a scale-up account and be listed on a current valid Dynochem license

- The EDS is a foundation for future enhancements that leverage access to equipment data for many other everyday applications

- The EDS will support a greater number of database fields, requested by customers to better describe your broad range of equipment types, including biologics set-ups.

- Help page on Vessel Update

- KB Article on Equipment Data Service

- 30-minute webinar on Equipment Data Service